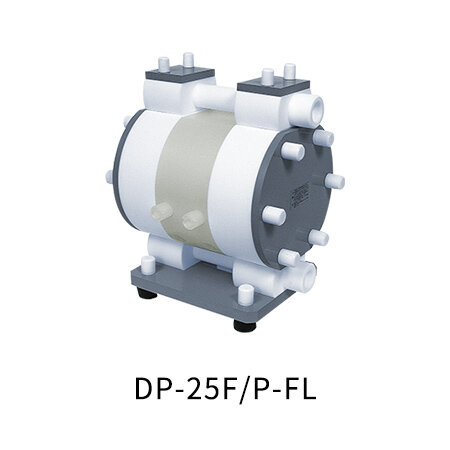

DP-F/P series

Corrosion-resistant Non-metallic Specification!

F series with Consideration to the Environment Where the Pump is Installed. This is a diaphragm pump with a fiber-optic stroke sensor built into the DP-FE series and is explosion-proof. Even if the one-piece diaphragm is damaged, metal ion contamination is prevented, and the pump can be operated with peace of mind in a corrosive environment. Suitable for transfer of CMP slurry. The air switch valve employs the non-metallic specification PEEK spool.

Standard seal specification, and the flat valve type is optional (built-to-order). Contact us for more details.

■ Main Applications

Transfer of Flammable Liquids in Explosion-proof Areas/Transfer of Chemicals, Pure Water, and Waste Liquids

Features

■ Seal Specification

| Standard Seal A PVC seal that absorbs changes in the dimensions of the join section for the fluorine resin pump. |

|

|

■ Non-Metallic Specification

| One-piece Diaphragm Center disk diaphragm with integrated center disk and diaphragm. Replacement is extremely simple, and it has excellent running costs. |

Resin Center Rod By using resin as the center rod material, non-metal is achieved. |

|

|

|

■ Employs Non-Metallic Specification PEEK Spool

The air switch valve employs a non-metallic specification PEEK spool.

◆ Air Switch Valve “PEEK Spool”

| PEEK Resin Is Employed for the Spool Valve and Engineering Plastic Is Employed for the C-spring. This prevents operation failure due to rusting of the spool, or metal ion contamination that arises from transfer liquid penetrating the switch mechanism due to diaphragm damage. |

|

Specifications

| Valve Shape and Model Number | ||||

| Ball Valve |

DP-20F/P |

DP-25F/P |

DP-38F/P |

|

| Flat Valve | - | Built-to-order (Contact us.) | ||

| Body Material | ||||

| Center Body | Polypropylene (PP) | HDPE, Polypropylene (PP) |

||

| Pump Body | PTFE | |||

| Wetted Parts Material | ||||

| Diaphragm | PTFE | |||

| Valve | ||||

| Valve Seat | ||||

| Valve Stopper |

||||

| Center Disk | Integrated with diaphragm | |||

| Specifications | ||||

| Nominal Diameter | 3/4" (20 mm) | 1" (25 mm) | ||

| Material Connection |

Suction Port | JIS flange 10K 20A equivalent | JIS flange 10K 25A equivalent | |

| Discharge Port | ||||

| Air Connection |

Supply Port | Rc 1/4 | Rc 3/8 | Rc 1/2 |

| Exhaust Port | Rc 3/8 | Rc 3/4 | ||

| Air Supply Pressure | 0.2~0.5 MPa *1 | |||

| Maximum Discharge Pressure | 0.5 MPa | |||

| Water Discharge/Cycle |

160 mL *2 | 300 mL *2 | 700 mL *2 | |

| Maximum Flow Rate | 30 L/min | 60 L/min | 70 L/min | |

| Maximum Air Consumption | 400 L/min (ANR) | 600 L/min (ANR) | 1000 L/min (ANR) | |

| Maximum Size Solid | Maximum 2 mm *3 | Maximum 3 mm *3 | ||

| Viscosity Limit | Maximum 2 Pa·s | Maximum 2.5 Pa·s | ||

| Temp Range |

Ambient | 0~70 °C | ||

| Liquid Temperature | 0~80 °C | |||

| Noise Level | 85 dB | 88 dB | 90 dB | |

| Net Weight | 14.8 kg | 32.0 kg | 52.0 kg | |

*1 The compressed air quality shall satisfy quality classes both 2 and 3 specified in “JIS B8392-1:2000 Compressed air for general use.” (Maximum particle diameter: 1 μm, Maximum open air pressure: -20°C, Maximum oil concentration: 0.1 mg/m3) The maximum supply air pressure of a type with a resin-made pump body depends on the liquid temperature.

*2 The water discharge is provided as a rough approximation only. The discharge will differ depending on factors such as the liquid to be transferred and the piping conditions.

*3 The flat valve type cannot handle slurry.

Dimentional drawing

Performance curve

Downloads

Parts List

| Valve Shape and Model Number | ||||

| Ball Valve | DP-20F/P (854804) |

DP-25F/P Built-to-order (Contact us.) |

DP-38F/P (853946) |

|

| Flat Valve | - | Built-to-order (Contact us.) | ||