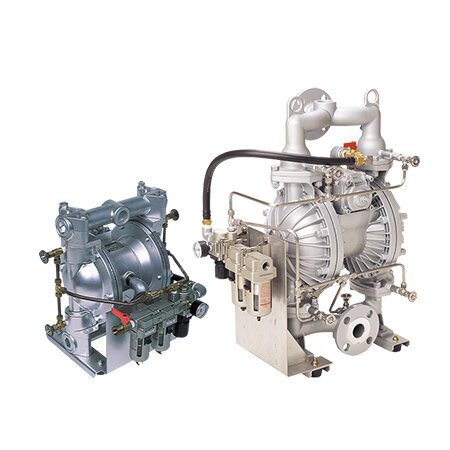

Powder Pump (Special specifications)

For Improving the Work Environment and Work Efficiency! Safe Design with Intrinsically Explosion-proof Specification.

A diaphragm pump that can transport low density powders such as diatomaceous earth, silica, and powder coatings.

It can be installed at low cost, as it does not require electrical work and the equipment can be simplified.

The pump is compact and has explosion-proof specifications, so it can be used safely without taking up space.

■ Main Applications

Transport of Diatomaceous Earth (Powder)/Transport of Powder Coatings

Features

■ Can Transport Low Density Powders such as Diatomaceous Earth, Silica, Powder Coatings and Toners.

We have models that are capable of handling from 200 kg to 1500 kg per hour, with little separation phenomena or dust.

● Examples of Powders that Can be Transported

Toner/powder coatings/aerosols/silica/glass bubbles/calcium carbonate/carbon black/pesticides/medical powders/diatomaceous earth, etc.

■ Can be Installed at Low Cost Due to not Requiring Electrical Work and the Equipment Can be Simplified.

Useful for improving the work environment as it is a self-suction type and the flow rate can be controlled with ease.

■ Yamada’s Proprietary Design Air Switch Valve “C-Spool”

The air switch valve in the center section of the diaphragm pump is completely oil-free, so it does not require regular lubrication.

The operation assist using a C-spring suppresses stoppages during operation, and achieves stable operation.

◆ Air Switch Valve “C-Spool”

| The C-spring Prevents Stoppages during Operation Achieves stable operation. |

Equipped with a Reset Button Downtime due to pump stoppages in the case of wear of the air switch valve is kept to a minimum. |

|

|

| Completely Oil-free Both the air switch valve and the pilot valve that activates the air switch valve at the stroke limit are designed to be oil-free. Does not require regular lubrication. |

Simple Replacement No need to disassemble the pump when replacing it. |

|

Specifications

| Body Material | A: Aluminum(ADC12) | A: Aluminum(ADC12) S: Stainless Steel (SCS14) |

|||

| Diaphragm Material (Pump body: Aluminum type) | |||||

| C: Neoprene (CR) |

NDP-25BAC powder | NDP-40BAC powder | NDP-50BAC powder | NDP-80BAC powder | |

| N: Buna N (NBR) |

NDP-25BAN powder | NDP-40BAN powder | NDP-50BAN powder | NDP-80BAN powder | |

| E: EPDM | NDP-25BAE powder | NDP-40BAE powder | NDP-50BAE powder | NDP-80BAE powder | |

| Diaphragm Material (Pump body: Stainless steel type) | |||||

| C: Neoprene (CR) |

NDP-25BSC powder | NDP-40BSC powder | NDP-50BSC powder | NDP-80BSC powder | |

| N: Buna N (NBR) |

NDP-25BSN powder | NDP-40BSN powder | NDP-50BSN powder | NDP-80BSN powder | |

| E: EPDM |

NDP-25BSE powder | NDP-40BSE powder | NDP-50BSE powder | NDP-80BSE powder | |

| Wetted Parts Material | |||||

| Ball Valve | Same as the diaphragm material | ||||

| O-ring | B〇C, B〇N: NBR B〇E: EPDM | ||||

| Valve Seat | NDP-25BA□: SMS1025NDP-25BS□: SUS316 | Same as the diaphragm material | |||

| Valve Stopper | Same as the body material (integrated type) | ||||

| Center Disk | SUS316 | A5056 | |||

| Specifications | |||||

| Nominal Diameter | 1" (25 mm) | 1·1/2" (40 mm) | 2" (50 mm) | 3" (80 mm) | |

| Material Connection |

Suction Port | Rc 1 | JIS flange 10K 40A equivalent |

JIS flange 10K 50A equivalent |

JIS flange 10K 80A equivalent |

| Discharge Port | Rc 1 | JIS flange 10K 40A equivalent |

JIS flange 10K 50A equivalent |

JIS flange 10K 80A equivalent |

|

| Air Connection |

Supply Port | Rc 3/8 | Rc 1/2 | Rc 3/4 | Rc 3/4 |

| Exhaust Port | Rc 3/4 | Rc 1 | |||

| Air Supply Pressure | 0.2~0.7 MPa | ||||

| Maximum Flow Rate | Approx. 200 kg/h * | Approx. 500 kg/h * | Approx. 1000 kg/h * | Approx. 1500 kg/h * | |

| Maximum Air Consumption | 1600 L/min (ANR) | 4000 L/min (ANR) | 6000 L/min (ANR) | 6000 L/min (ANR) | |

| Net Weight | BA□: Approx. 14 kg BS□: Approx. 21 kg |

BA□: Approx. 30 kg BS□: Approx. 46 kg |

BA□: 38.0 kg BS□: 66.0 kg |

BA□: 66.0 kg BS□: 115.0 kg |

|

*The water discharge is provided as a rough approximation only. It will differ depending on the usage conditions, etc.

The capability will differ depending on the powder to be transported, so confirmation using a demonstration machine will be needed.

For inquiries regarding test usage and delivery, contact your nearest Yamada Corporation sales office.