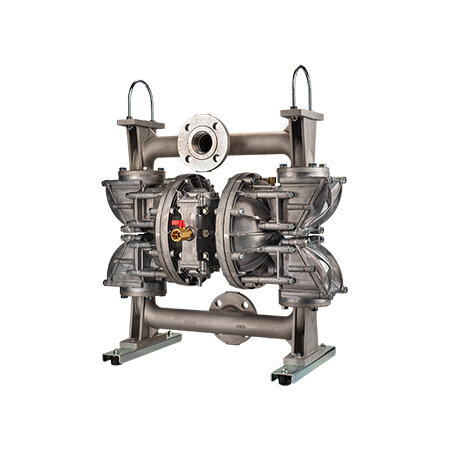

Flap Valve Pump (Special specifications)

High Water Discharge! Safe Design with Intrinsically Explosion-proof Specification.

A diaphragm pump that is useful for the transport of factory wastewater and muddy water containing sediment, and is equipped with a flap-type valve that can allow solids up to 30 mm to pass through.

The safety structure does not require explosion-proof measures, so it can be used anywhere.

There is no concern about liquid leakage due to wear of the seal, and issues such as failure due to winding, and inconveniences such as noise and maintenance inspections are resolved.

By simply opening and closing the valve, cutting off the flow at the end point is possible or water discharge can be controlled easily and safety.

The flap valve pump has a nominal diameter of 2" (50 mm) and maximum flow rate of approximately 600 L/min.

The maximum size solid is 30 mm or less.

■ Main Applications

Drainage from Civil Engineering Construction Works/Pumping of Muddy Water Containing Sediment/Drainage of Grey Water from Sewage Treatment Plants, Livestock Farms, and Food Factories/Drainage from Coal Mines, Combustible Gas and Petrochemical Plants

Features

■ Pump for Factory Wastewater, Can Transfer Liquids and 30 mm Solids at the Same Time.

A new-style positive displacement-type reciprocating diaphragm pump that powerfully sucks and discharges liquid including sediment and deposits, and transfers liquid and 30 mm solids at the same time.

| ■ Difficult for Solids to Accumulate, and is Capable of Self-Suction. |

|

Due to the liquid flow direction, namely having the material suction port in the upper part of the pump and the delivery port in the lower part, and a swing valve that flaps, the structure makes it difficult for solids to accumulate inside the pump. |

|

|

| ■ Operation Principles |

|

1. When compressed air is sent to the air chamber on the left side, the center rod shifts in the left direction, pushing out the material of the material chamber, and material is sucked into the material chamber on the right side at the same time. 2. When the center rod shifts to the left for a full stroke, the switching valve is activated, and the compressed air is sent to the right air chamber, shifting the center rod in the right direction. |

■ Yamada’s Proprietary Design Air Switch Valve “C-Spool”

The air switch valve in the center of the diaphragm pump is completely oil-free, so it does not require regular lubrication. The operation assist using a C-spring suppresses stoppages during operation, and achieves stable operation.

◆ Air Switch Valve “C-Spool”

| The C-spring Prevents Stoppages during Operation Achieves stable operation. | Equipped with a Reset Button Downtime due to pump stoppages in the case of wear of the air switch valve is kept to a minimum. |

|

|

| Completely Oil-free Both the air switch valve and the pilot valve that activates the air switch valve at the stroke limit are designed to be oil-free. Does not require regular lubrication. |

Simple Replacement No need to disassemble the pump when replacing it. |

|

Specifications

| Body Material |

A: Aluminum (ADC12/AC4C) |

||

| Diaphragm Material | |||

| N: Buna N (NBR) |

NDP-50FAN (854296) |

||

| Wetted Parts Material | |||

| Flap Valve |

NBR SPCC (Insert material) |

||

| Valve Seat |

HNBR SPHC (Insert material) |

||

| Center Disk |

A5056 | ||

| Nominal Diameter |

2"(50 mm) | ||

| Material Connection |

Suction Port |

JIS flange 10K 50A equivalent and Rc 2 |

|

| Discharge Port |

|||

| Air Connection |

Supply Port |

Rc 3/4 | |

| Exhaust Port |

Rc 1 | ||

| Air Supply Pressure |

0.2~0.7 MPa | ||

| Maximum Discharge Pressure |

0.7 MPa | ||

| Water Discharge/Cycle |

2400 mL *1 | ||

| Maximum Flow Rate |

600 L/min *2 | ||

| Maximum Air Consumption |

7000 L/min (ANR) | ||

| Maximum Size Solid |

Spherical | Maximum Ø30 mm | |

| Cylindrical | Maximum Ø15 mm x 45 mm | ||

| Suction Head Lift |

5 m | ||

| Net Weight |

52.0 kg | ||

*1 The water discharge is provided as a rough approximation only. The discharge will differ depending on factors such as the liquid to be transferred and the piping conditions.

*2 Maximum flow rate is a value indicating the pump capacity. We recommend selecting a size that allows some leeway, taking into account the impact on the life span of the diaphragm.

Dimentional drawing

Performance curve

Downloads

Parts List

| Body Material |

A: Aluminum (ADC12/AC4C) |

||

| Diaphragm Material | |||

| N: Buna N(NBR) |

NDP-50FAN (854296) |

||