DP-F/N series

Corrosion-resistant Non-metallic Specification! Safe Design with Intrinsically Explosion-proof Specification.

An air-powered chemical pump with external timer control that is suitable for chemicals supply systems and filtration. A non-metallic model corrosion-resistant diaphragm pump that uses resin as the material even for the main parts.

Even if the one-piece diaphragm is damaged, metal ion contamination is prevented, and the pump can be operated with peace of mind in a corrosive environment, so it is suitable for CMP slurry transfer.

■ Main Applications

Transfer of Flammable Liquids in Explosion-proof Areas/Transfer of Chemicals, Pure Water, and Waste Liquids

Features

■ Seal Specification

| Standard Seal A PVC seal that absorbs changes in the dimensions of the join section for the fluorine resin pump. |

|

|

■ Non-Metallic Specification

| One-piece Diaphragm Center disk diaphragm with integrated center disk and diaphragm. Replacement is extremely simple, and it has excellent running costs. |

Resin Center Rod By using resin as the center rod material, non-metal is achieved. |

|

|

|

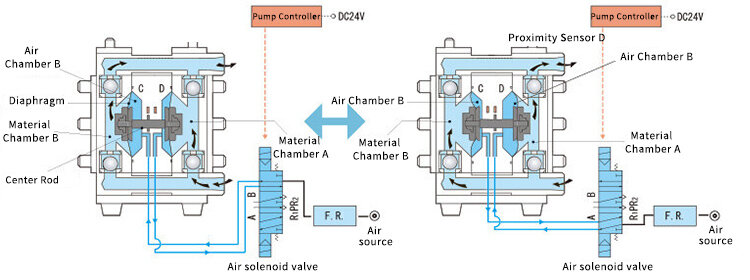

■ Air-Powered Chemical Pump with Timer Control

It employs a timer control by which the pump controller controls that cycle speed of the pump.

◆ Timer Control

| Manages the Pump Cycle Speed The pump controller manages the cycle speed of the pump by intentionally controlling the switching of solenoid valve. It can also detect diaphragm damage, pump controller failure, etc. |

|

|

Specifications

| Valve Shape and Model Number | |||||

| Ball Valve |

DP-10F/N |

DP-10F/N |

DP-20F/N |

DP-20F/N |

|

| Body Material | |||||

| Center Body | Polypropylene (PP) | ||||

| Pump Body | PTFE | ||||

| Wetted Parts Material | |||||

| Diaphragm | PTFE | ||||

| Valve | |||||

| Valve Seat | |||||

| Valve Stopper |

|||||

| Center Disk | Integrated with diaphragm | ||||

| Specifications | |||||

| Nominal Diameter | 3/8" (10 mm) | 3/4" (20 mm) | |||

| Material Connection |

Suction Port | Rc 3/8 (F) | JIS flange 10K 10A equivalent |

Rc 3/4 (F) | JIS flange 10K 20A equivalent |

| Discharge Port | |||||

| Air Connection |

Supply Port | Rc 1/4 x 2 (Common supply and exhaust port x 2) *1 | |||

| Exhaust Port | |||||

| Air Supply Pressure | 0.2~0.5 MPa *2 | ||||

| Maximum Discharge Pressure | 0.5 MPa | ||||

| Switching Speed | 0.2~0.5 sec./cycle *3 | 0.5~1.0 sec./cycle *3 | |||

| Water Discharge/Cycle |

60 mL *4 | 180 mL *4 | |||

| Maximum Flow Rate | 22 L/min | 35 L/min | |||

| Maximum Air Consumption | 350 L/min (ANR)*5 | 400 L/min (ANR)*5 | |||

| Maximum Size Solid | Maximum 1 mm | Maximum 2 mm | |||

| Viscosity Limit | Maximum 1 Pa·s | Maximum 2 Pa·s | |||

| Temp Range |

Ambient | 0~70 °C | |||

| Liquid Temperature | 0~80 °C | ||||

| Noise Level | 82 dB | 85 dB | |||

| Net Weight | 6.4 kg | 14.2 kg | |||

*1 The pipe length from the air supply valve (solenoid valve, etc.) to the pump shall be 1.5 m or less. If piping from the exhaust port of the air supply valve to another location, the pipe length to the end of the exhaust port shall be 5 m or less.

*2 The maximum supply air pressure for a type with a resin-made pump body will depend on the liquid temperature.

*3 If the stroke is limitless (no exhaust), up to 10 sec./cycle is possible.

*4 The water discharge is provided as a rough approximation only. The discharge will differ depending on factors such as the liquid to be transferred and the piping conditions.

*5 If the switching speeds are 0.2 sec./cycle (10F/N) and 0.5 sec./cycle (20F/N).

• For driving the pump, the pump controller with timer control (MFC-24) or P.L.C, and center exhaust type 3-position 5-port solenoid valve are required separately.

• The drive pump with external timer control has a structure (P.T.A) that allows the air chamber-side air pressure to escape when a certain stroke (length) is exceeded so that there is no stress on the diaphragm, so adjustment is necessary depending on the pump size in order to use the air efficiently.