AD-TT series

A Pulsation Dampener That Suppresses Pulsation and Prevents Pump Damage

A PTFE-specification pulsation dampener dedicated for F series. A pulsation dampener with a wetted part made of fluorine resin, which uses compressed air to suppress pulsation of liquid transported by the diaphragm pump.

Use at plants where pulsation is not acceptable, such as for protection of filters and one-shot spraying.

■ Main Applications

Prevention of Piping Vibration/Protection of Filters

Features

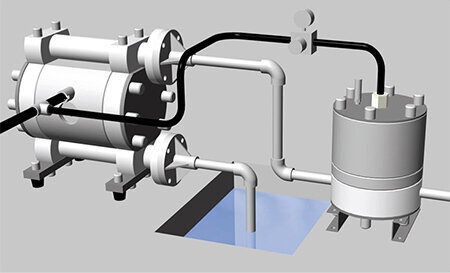

| ■ Installation Diagram |

|

|

[Note] |

Specifications

| Model Number | ||||

| AD-10TT (851918) |

AD-25TT (851919) |

AD-38TT (853441) |

||

| Body Material | ||||

| Center Body | Polypropylene (PP) | HDPE | ||

| Pump Body | PTFE | |||

| Wetted Parts Material | ||||

| Diaphragm | PTFE | |||

| Specifications | ||||

| Nominal Diameter | 3/8" (10 mm) | 3/4" (20 mm) | 1" (25 mm) | |

| Material Connection |

Suction Port | Rc 3/8 (F) | Rc 3/4 (F) | Rc 1 (F) |

| Discharge Port | ||||

| Air Connection |

Supply Port | Rc 1/4 | ||

| Exhaust Port | Rc 3/8 | |||

| Air Supply Pressure | 0~0.5 MPa *1 | 0~0.7 MPa *1 | ||

| Maximum Discharge Pressure | 0.5 MPa | 0.7 MPa | ||

| Maximum Air Consumption | 20 L/min (ANR) | |||

| Maximum Size Solid | Maximum 1 mm | Maximum 3 mm | ||

| Temp Range |

Ambient | 0~70 °C | ||

| Liquid Temperature | 0~80 °C | |||

| Net Weight | 4.4 kg | 11.7 kg | 30.0 kg | |

*1 The compressed air quality shall satisfy quality classes both 2 and 3 specified in “JIS B8392-1:2000 Compressed air for general use.”

(Maximum particle diameter: 1 μm, Maximum open air pressure: -20°C, Maximum oil concentration: 0.1 mg/m3)

The maximum supply air pressure of a type with resin-made pump body depends on the liquid temperature. The water discharge is provided as a rough approximation only. The discharge will differ depending on factors such as the liquid to be transferred and the piping conditions.

Dimentional drawing

Performance curve

Downloads

Parts List

| Model Number | ||||

| AD-10TT (851918) |

AD-25TT (851919) |

AD-38TT (853441) |

||