Pumping antifreeze to assembled machines

- Product model:

- NDP-25BPS

- Industry / Branch:

- Machinery

- Factory type / Production of:

- Heavy equipment production

The customer wanted to transfer antifreeze liquid from his storage to the filling station.

New assembled machines would need to be filled with operating fluids.

The capacity required was 13 l/min. The pipeline length was around 150 meters.

Calculated pressure loss around 1.5 bar.

Under these conditions our Yamada NDP-15BPS would have been sufficient, but we selected our Yamada NDP-25BPS to create a convenient buffer. When the nozzle in the filling point was opened, the pump started working,but would slow down until it would come finally to a complete stop.

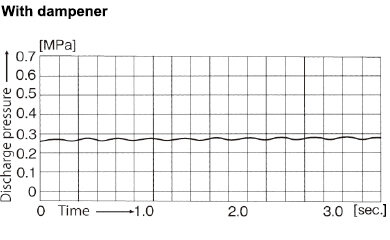

We added a dampener and the problem was solved.

The mass of the liquid in the pipeline needed so much power to get transferred, that the pump diaphragm would not be able to provide it. But with the dampener, with each stroke, the pump would push the liquid in the dampener first, compress the air inside and between the pump strokes, this accumulated pressure would help to keep the liquid moving. As we used a passive dampener, without diaphragm, after some time, the air would leave the chamber with the pumped liquid, so it was necessary to suck a bit of air to refill the dampener.

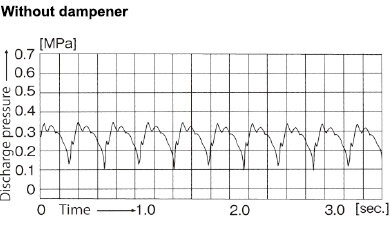

Comparison fluid pulsations with and without dampener use