Lithium-Ion Battery Manufacturing Process

- Industry / Branch:

- Battery

- Factory type / Production of:

- Battery manufacturing process

As companies become more environmental and energy efficient, the demand for technology and power increases, as does the need for more batteries.

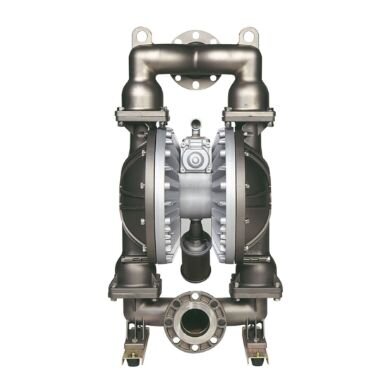

Did you know that Yamada diaphragm pumps are used in two-phases of the battery manufacturing process?

In the first phase, Yamada pumps are used to balance the concentration and viscosity from the transfer tank, to the storage tank, and then to the mixing process side.

In the next phase, material is then transferred to secondary tanks to complete the coating process. It is here where you will find Yamada pumps installed before and after the coating machine. In order to keep the concentration and viscosity consistent, Yamada pumps must be operational 24/7; making them one of the most reliable and efficient pumps on the market.

Yamada diaphragm pumps can handle a wide variety of chemical and power applications and do not contain zinc or copper; meeting the strict requirements of the lithium-ion battery manufacturing process.

YAMADA Pump Benefits

- Portable

- Variable Flow Rate and Discharge Pressure

- Bolted Leak-Free Design

- Broad Chemical Compatibility

- Self-Priming

- Chemical Resistant Stainless Steel & Polypropylene Pumps

- Cannot Overheat

- Deadhead

- Pumping Efficiency Remains Constant