YAMADA PUMP:Blog

Check Ball Valve Wedged In Valve Seat!! - What has caused this problem?

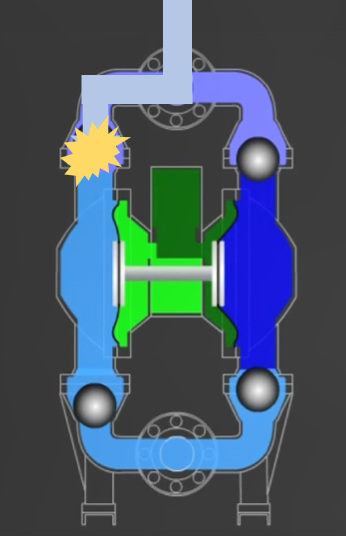

An Air-Operated Double Diaphragm Pump (hereafter 'AODD pump') has four check valves in it. The check valves are placed at the inlet and outlet of each liquid chamber. The reciprocating motions of the diaphragms and those check valves enable the pump to move liquid in a continuous flow. However, the ball- shaped check valves can be wedged into the valve seat as the cover photos of this article, which causes pump malfunctions. Then what has caused this issue? Also, what countermeasure can be taken to avoid this problem?

What has caused the issue?

The bottom line is that this is often caused by liquid pressure from discharge line. When the pump is being deadheaded for a long time or the temperature inside the discharge pipeline rises, the liquid expansion can happen in the pipeline. Then the liquid pressure in the discharge line returns to the pump through the liquid outlet, and it strongly pushes the check valve ball into the valve seat.

Image of liquid returning to the pump from dischare line

Consequently, the balls will become deformed and need to be replaced. To make matters worse, the check valve ball can even go through the valve seat. Or this phenomenon can damage the pipelines or the valves along the pipelines.

Countermeasures

There are several countermeasures for this problem. The first is to install a bypass relief valve to release the air pressure. Especially, if the pumps need to be placed in an environment that easily changes the liquid volume - e.g. high temperature, and so on, - placing a bypass relief valve at the liquid discharge point is an effective measure. Or another is to cover the pipeline with some insulating material to prevent the temperature from increasing.

Contact us for more information about YAMADA AODD pumps.