YAMADA PUMP:Blog

Bent Centre Rod!! What has caused this issue?

There are two conceivable causes as follows;

Cause 1: Starting the pump with slurry being accumulated on the bottom of the liquid chamber.

When starting the pump with slurry sediment remaining on the bottom of the liquid chambers, it will damage the centre rod and the diaphragm. When transferring slurry and temporarily stopping the pump operation, please take the slurry out of the liquid chambers and clean the chambers well before resuming the pump. Without such a routine maintenance, it will also cause some other issues such as abrasion or crack on the diaphragm surface (pic. 1), or wear on the centre disk (pic. 2).

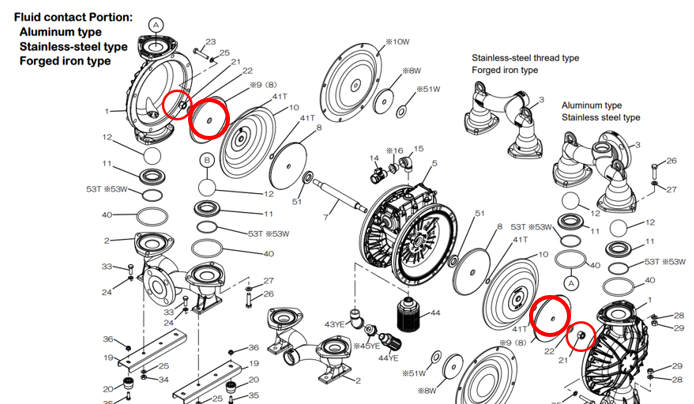

Pic. 1: Abrasion & Crack on Diaphragm Surface Caused by Slurry

Pic. 2: Wear on Centre Disk Caused by Slurry

Cause 2: Loose nut or centre disk

Whether or not the liquid contains solid materials, this issue can happen. In this case, it can be attributed to the loose nut or centre disk (see pic. 3 below). The nut can be loosened if it is reused too repeatedly. Therefore, changing the nut routinely is a solution to this problem.

Contact us for more information about YAMADA AODD pumps.