YAMADA PUMP:Blog

Maximum Flow Rate - Is it an important criterion?

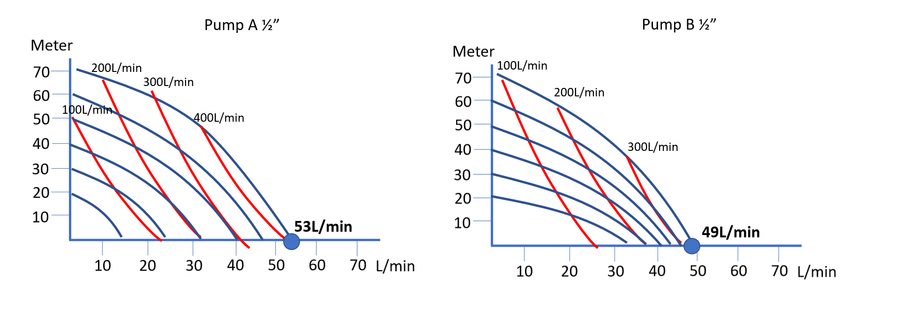

Assuming that both Pump A and B shown below are 1/2" sizes from different suppliers, it may seem Pump A is better than B in terms of the efficiency because the maximum flow rate of Pump A is higher than B - i.e. 53LPM versus 49LPM. It is true that the maximum flow rate is one of the most noticeable points in pump specifications, and this may lead to the misunderstanding stated earlier. In order to more properly judge which pump is more appropriate, however, there are more important factors to take into consideration. This article discusses a number of criteria to focus on in order to decide which of them to select.

Point 1: To understand the desired flow rate and the air consumption & air supply pressure required to fulfill the desired capacity.

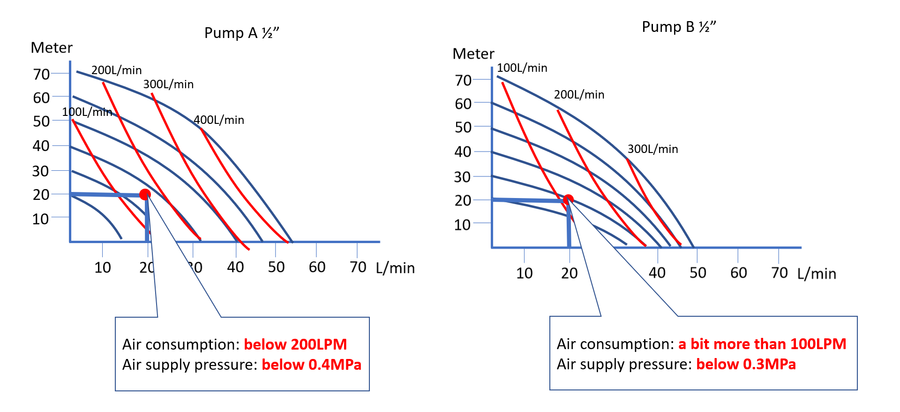

One of the most important things is to understand that Pump A is not always more efficient than Pump B because its maximum flow rate is higher than that of Pump B. In other words, if the maximum flow rate of Pump A is higher, it does not mean that Pump A always uses less air than Pump B at any fluid discharge volume.

In fact, Pump B consumes less air with less supplied air pressure, if the required water discharge volume is 20LPM and the discharge head is 20 meters. As the graphs below say, the amount of the air required for Pump A to fulfill the required capacity stipulated above is between 150LPM and 200LPM, and the air supply pressure is in the middle between 0.3 - 0.4MPa. On the other hand, Pump B requires a little more than 100LPM of air, and the air pressure is below 0.3MPa.

Therefore, the point is to understand the air volume and pressure needed to meet the required flow rate, rather than focusing on the maximum capacity of the pump.

Point 2: If the desired flow rate is very close to the maximum capacity of the pump, using a larger pump can be a better option.

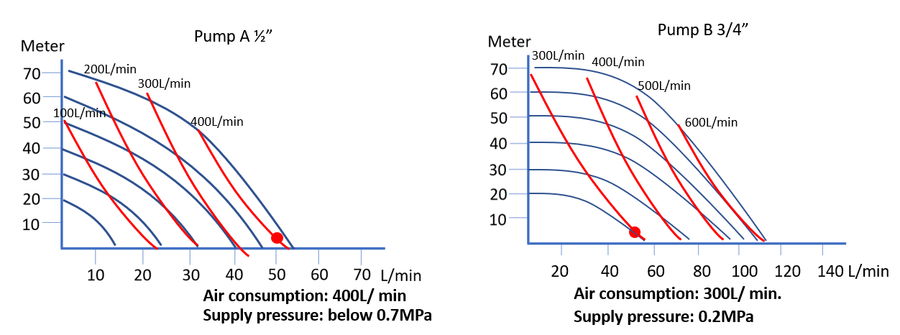

It might seem Pump A is the only option when the required water discharge volume is 50LPM water, - in fact, 50LPM is within the capacity of Pump A but not Pump B. If the pump size cannot be changed for a certain reason, Pump A should be the choice. If it is possible to change the pump size, however, using a larger pump can be a better choice for two reasons, - there might be a counter opinion against it because it seems to be more beneficial to use a smaller pump, which is usually less expensive than a larger one, to cover the desired capacity.

The first reason is the energy-saving performance. That is, a larger pump tends to consume less air than a smaller one to pump the same amount of fluid. The two graphs below show the performance curves of 1/2" of Pump A and 3/4" of Pump B. If the desired capacity is 50LPM at the discharge head 1 meter with Pump A, the amount of air required by Pump A 1/2" pump is 400LPM, and the supply air pressure is a bit below 0.7MPa. On the other hand, the 3/4" Pump B requires only 300LPM air and the air supply pressure 0.2MPa.

The second reason is the longevity of component parts. As stated above, the 1/2" Pump A requires way higher amount of air and air pressure than the 3/4" Pump B to discharge 50LPM water. It means the larger amount of air goes through the air inlet with higher pressure of the smaller pump; the higher air pressure more strongly pushes the smaller diaphragms; the diaphragm stoke moves faster, and that the check valves open and close more quickly and more frequently. Consequently, the component parts are more easily damaged or worn out, and need to be replaced more frequently. Those situations will finally increase the frequency to procure consumable parts and increase downtime for maintenance.

Images of pump operations with higher & lower air consumption and pressure

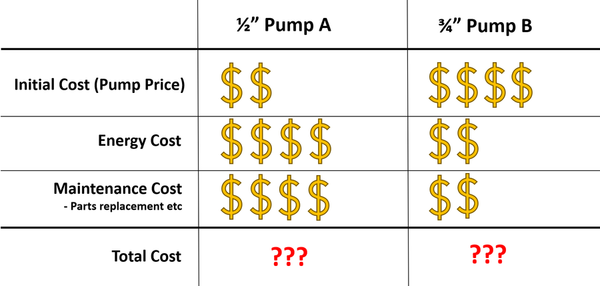

It is true that using a smaller pump to transfer as much fluid as possible seems to be a good way to reduce the initial cost. Considering the two points discussed above, however, using a smaller pump to discharge large amounts of liquid may cost more than using a larger pump in the long run, as shown in the table below.

Conclusion

If the maximum flow rate of a certain pump is higher than the other, then the pump seems to be a better one. However, this is not always true. What is more important is to understand what the amount of air needed to meet the desired fluid discharge volume is. In addition, if the desired flow rate is very close to the maximum capacity of the pump, using a larger pump can be more economical in the long run.

Contact us for more information about YAMADA AODD pumps.