YAMADA PUMP:Blog

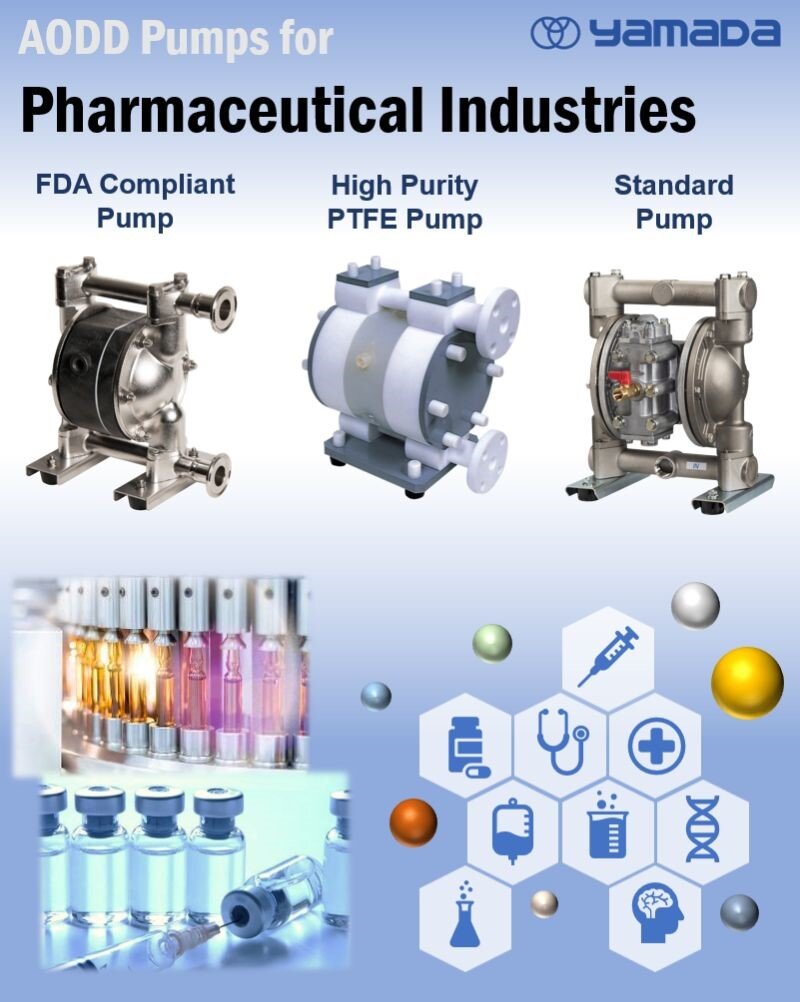

Yamada AODD Pump for Pharmaceutical Industries!

In pharmaceutical industries, AODD pumps are used to transfer alcohols, solvents, disinfectants, water and so on.

<Features & Benefits>

- Yamada AODD pumps are intrinsically safe, as they are air-driven;

- They are compact in comparison with some other kinds of pumps and can save the space.

- The simple structure makes the teardown & reassembly easy and reduce downtime, which helps a lot for the frequent cleaning work!

<Popular Models>

1) FDA Compliant Pumps

Yamada FDA compliant pumps include 316 Stainless Steel wetted components with Passivated Satin Finish, PTFE-Coated or Polypropylene Air Motor*, Sanitary Clamp Fittings, and FDA compliant elastomers: TPEE, EPDM and PTFE.

2) High Purity PTFE Pumps

This series was designed specifically for the process where purity is of the utmost concern. It has no internal metal components, so even a diaphragm failure will not produce a single PPB of ionic contamination. To ensure maximum corrosion resistance, purity levels and low particle generation, all wetted parts are machined from 100% virgin PTFE.

3) Standard AODD Pumps

The available sizes range from ¼" to 3". There are also various body and diaphragm materials, depending on the fluid to be transferred!

Contact us for more information about YAMADA AODD pumps.